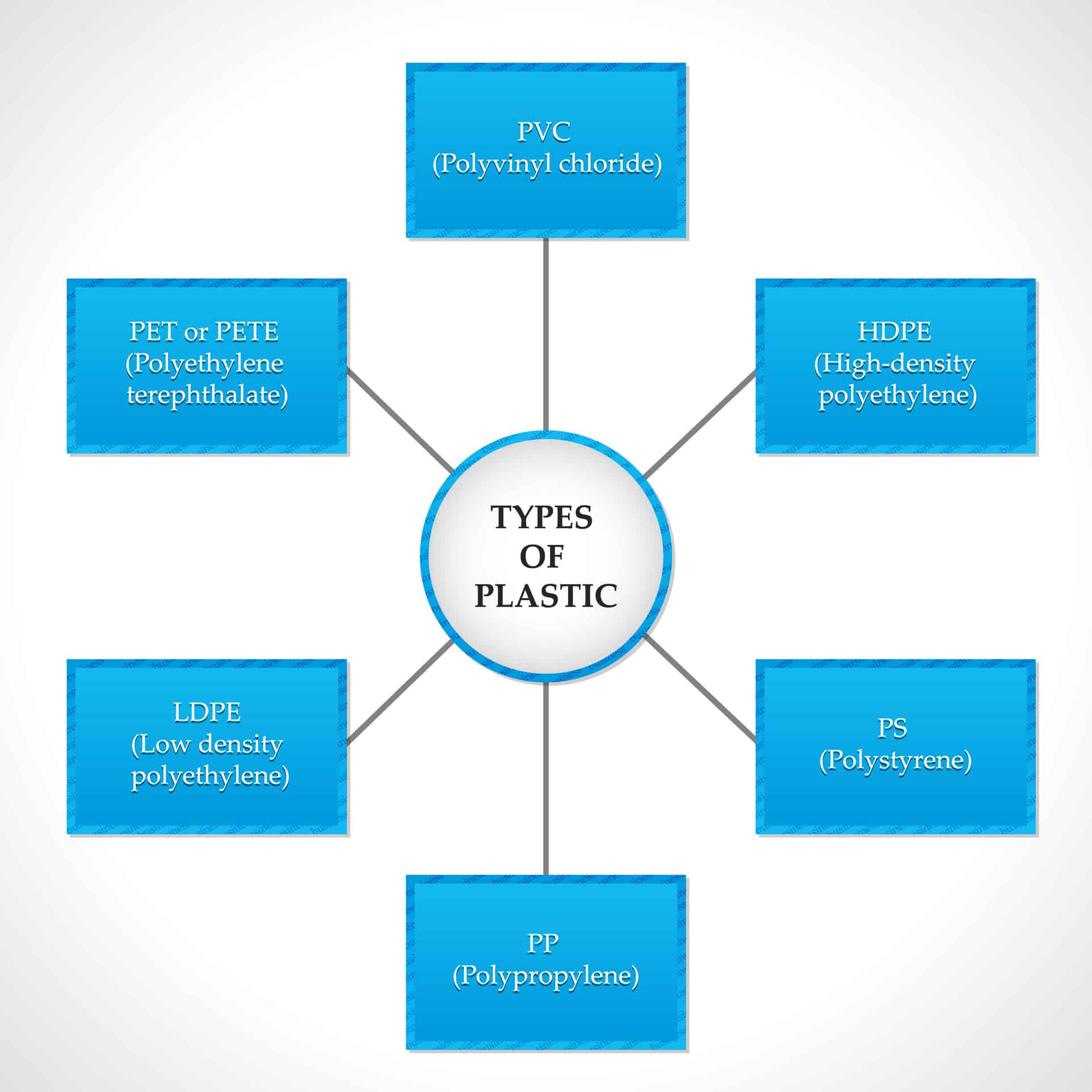

Plastics

A wide variety of plastics are used for cosmetic packaging, increasingly replacing glass. Whereas plastics were previously only used for packaging components such as closures, caps, stoppers and seals, their use has rapidly expanded in recent years to include the manufacture of complete primary packaging in the form of bottles, bags, jars, sachets and even aerosol cans. The main advantages over other packaging materials are their practical unbreakability, thermal deformability and low weight. On the other hand, the risk of higher interactions with the contents is a disadvantage. In addition, plastics have a higher permeability to liquids and gases than glass. This is noticeable to customers in the form of labels coming off, or bottles becoming bloated or shrunk.

Polyethylene (LDPE/HDPE)

Polyethylene (PE) is a semi-crystalline thermoplastic obtained by polymerisation of ethylene. The mechanical properties of PE are influenced by the degree of crystallinity and average molecular weight of the polymer as well as by external conditions such as temperature. LDPE/HDPE plastics are manufactured by low-pressure and high-pressure polymerisation.

Low-pressure polymerisation uses pressures of 1 to 50 bar and temperatures of 20 to 150 °C (Ziegler process) as well as pressures of 30 to 40 bar and temperatures of 85 to 180 °C (Phillips process). This produces linear polyethylenes such as HDPE with short side chains, few branches, a high degree of crystallinity and high density.

High-pressure polymerisation at 1000 to 3000 bar and temperatures of 80 to 300 °C produces branched macromolecules with long-chain branches, a low degree of crystallinity and low density. LDPE plastic is produced using this process.

LDPE has high toughness and flexibility, absorbs low amounts of water and is highly resistant to acids, alkalis, alcohol, water, fats and oils. Consumers recognise this type of packaging by its softer feel.

HDPE plastic is similar in its properties to LDPE, but is harder and stiffer. Due to its higher degree of crystallinity, it is more resistant to chemicals than LDPE.

Polycarbonate (PC)

Polycarbonate is an amorphous thermoplastic and is produced by polycondensation.

The plastic can be produced either from bisphenol A and diphenyl carbonate with the separation of phenol in a vacuum or by dissolving bisphenol A in pyridine and then reacting it with phosgene in the presence of indifferent solvents.

Bisphenol A polycarbonate is characterised by low density, high strength, rigidity, hardness and toughness in the range from -150 to +135 °C, crystal-clear transparency and low water absorption. However, due to its hydrolysable carbonate ester bonds, this plastic has only limited resistance to chemicals.

Polyvinyl chloride (PVC)

Polyvinyl chloride (PVC) is an amorphous thermoplastic material formed from vinyl chloride using the classic method of radical-initiated polymerisation. The degree of polymerisation is controlled by the reaction temperature.

PVC is manufactured on an industrial scale using three different polymerisation processes, which are briefly described below:

- Emulsion polymerisation (E-PVC)

A mixture of water and vinyl chloride is converted into a stable emulsion by adding emulsifiers while stirring.

The polymerisation is activated by water-soluble peroxides.

Spray drying processes the finely dispersed polymer into fine particles or larger fragments.

- Suspension polymerisation (S-PVC)

Vinyl chloride is broken down into very fine droplets in water in an autoclave through intensive stirring/homogenisation. The polymerisation is triggered by vinyl-soluble initiators. The monomer droplets then form solid polymer particles, which are separated from the aqueous phase, washed and dried.

- Mass polymerisation (M-PVC)

Monomer-soluble peroxides serve as initiators. At very high stirring speeds, a vinyl chloride conversion of up to 10% is achieved in the so-called pre-polymeriser. In a main polymeriser, this suspension is polymerised with further vinyl chloride and initiator additives to a conversion of 60-80%. M-PVC has a higher purity and transparency than S-PVC.

The manufacturing processes mentioned above influence the external appearance, such as grain size and grain uniformity, and thus also the plasticiser absorption capacity. PVC is used either in mixtures with a plasticiser content of 0-12% (hard PVC) or in mixtures with a higher plasticiser content (soft PVC).

Hard PVC is characterised by high mechanical strength, rigidity and hardness, and high resistance to chemicals. Soft PVC is characterised by adjustable flexibility, toughness and temperature-dependent resistance to chemicals. PVC is no longer used in cosmetics.

Polypropylene

After polyethylene, polypropylene is the most commonly used plastic in Europe.

Polypropylene is produced by coordination polymerisation using Ziegler-Natta catalysts, although metalocenes are increasingly being used today.

In propylene homopolymers, propene is the monomer, while in copolymers, ethylene, 1-butene or higher α-olefins can be used as co-monomers. The synthesis of the polymer results in either isotactic (all methyl groups point in one direction), syndiotactic (the orientation of the methyl groups is altered) or atactic (the arrangement of the methyl groups is unsymmetrical) polypropylenes. The isotactic polymer

is the most important polymer in this series. As the isotactic content increases, so does the degree of crystallinity.

Polypropylene is even more sensitive to light and oxidation than polyethylene, making the addition of antioxidants and UV stabilisers essential. To reduce costs, fillers such as minerals, chalk and talc are often used. Reinforcing materials such as glass fibre can also be added to achieve special properties. Like all polyolefins, polypropylenes are characterised by low water vapour permeability and are therefore often used to protect food.

Plastic additives

Due to the diverse requirements placed on modern cosmetic packaging, plastics such as those produced by polymerisation, polycondensation or polyaddition are rarely processed or used in their pure form.

They are usually mixed with additives.

Only the combination of polymers with various additives results in usable plastics whose processability and physical and chemical behaviour meet the requirements of modern cosmetic packaging.

The concentrations of additives range from approx. 0.05% (antioxidants) to 50% (plasticisers, antistatic agents).

The most commonly used additives are antioxidants, plasticisers, UV filters, UV stabilisers, heat stabilisers, lubricants, impact modifiers and antistatic agents.

The European Pharmacopoeia alone lists 22 additives that may be used in plastic containers for pharmaceutical purposes.

In pharmaceutical product development, tests are required to ensure that these additives are inert to the active ingredients.

Antioxidants to protect plastics

Antioxidants are added to the polymer to extend its service life by slowing down or preventing oxidative degradation caused by heat, light, UV radiation, shear stress during plastic processing, metallic impurities or traces of hydroperoxides from synthesis. The free radicals produced in this process can lead to degradation of the polymer. This process can result in chain scission, which leads to a decrease in molecular mass. Alternatively, however, cross-linking and a resulting increase in molar mass may occur. For the user, this is summarised as signs of ageing, which can manifest themselves in the form of yellowing, loss of gloss and transparency, surface cracks or loss of mechanical properties.

Antioxidants (AO) are divided into two groups: primary AO, which inhibit oxidation by reacting with chain-forming radicals (e.g. substituted phenols and aromatic amines), and secondary AO, which convert peroxides and hydroperoxides into non-radical stable compounds (e.g. phosphites, phosphonates, thio compounds).. One of the most commonly used antioxidants is still 2,6-di-t-butyl-4-methylphenol (‘butylated hydroxytoluene’, BHT).

Plasticisers

Plasticisers are used in plastics to increase their flexibility, processability and elasticity. A distinction is made between ‘internal plasticisation’ and ‘external plasticisation’. In internal plasticisation, two compatible monomers with widely differing glass transition temperatures are copolymerised, resulting in a strong chemical bond between hard and soft segments, which in turn results in temperature-dependent flexibility. External plasticisation (primary and secondary plasticisers) involves the addition of low-molecular substances. Incorporation into the polymer chains and the formation of secondary valence forces lead to swelling or solvation. Primary plasticisers should gel well and not migrate out of the polymer.

These include phthalic acid esters such as diethylhexyl phthalate (DEHP) or dibutyl phthalate (DBP), but also adipates such as di-(2-ethylhexyl) adipate (DEA), which is often combined with secondary plasticisers such as epoxidised soybean oil. Secondary plasticisers are dipolar, moderate gelling agents and are used in combination with primary plasticisers to reduce the tendency to migrate and to increase cold resistance and extraction resistance. Due to the ongoing discussion about the possible genotoxic potential of DEHP, its use is severely restricted and is deliberately avoided in pharmaceutical products, for example. In

UV filters/UV stabilisers

The absorption of ultraviolet light can lead to photochemical degradation in plastics, which is caused by the formation of radicals, possibly accompanied by oxidation. This can result in changes in colour, loss of flexibility and gloss, and changes in molar mass. Protective measures can include coatings such as metals or lacquers. It is also possible to use UV absorbers, which are capable of absorbing UV radiation and emitting infrared radiation. Representatives of this class are hydroxybenzophenones, hydroxyphenylbenzotriazoles and carbon black.

Furthermore, so-called quenchers, which absorb the excitation energy, are also used, e.g. nickel chelates.

Plastic lubricants

Lubricants reduce friction between solid particles. Most lubricants are made from natural raw materials, e.g. paraffins from petroleum residues and natural fatty acids from vegetable and animal fats (e.g. stearic acid).

The macromolecular structure results in melts with very high viscosity, which means that transport and deformation can only take place under the influence of pressure. This can lead to degradation of the polymer.

Additives that are capable of influencing the rheological properties of the polymer phase from within are referred to as internal lubricants.

They can reduce viscosity or have a shear-thinning and dissipation-reducing effect. Additives that determine the behaviour of the hot plastic mass at interfaces with other materials are referred to as external lubricants. They can have a separating or friction-reducing effect.

Impact modifiers for plastics

Impact modifiers (homopolymers or copolymers) are able to modify brittle polymers due to their low glass transition temperature so that they remain impact-resistant in cold conditions (absorption of impact energy without breaking). This property is important when packaging slips out of the hand and falls to the floor. In this case, the packaging must remain intact and not break. This property is also important for the manufacturer, as packaging is exposed to extreme temperature fluctuations and forces in global logistics.

Plastic antistatic agents

Antistatic agents reduce the static chargeability of plastics by evenly distributing and dissipating charges across the entire surface. External antistatic agents contain liquids with surface-active substances. Internal antistatic agents include ethoxylated tertiary amines of fatty acids. White packaging should remain white in the shop. However, if you look closely, you will often discover grey dust marks, especially if seasonal items have been on display for a while.

If you would like to know more about plastics, please do not hesitate to contact us.

Literature

Domininghaus, H.: Die Kunststoffe und ihre Eigenschaften (Plastics and their properties), 6th edition, Springer-Verlag Berlin Heidelberg (2005)

Gächter, R.; Müller, H.: Kunststoffadditive (Plastic additives), 3rd edition, Carl Hanser Verlag Munich Vienna (1989)

Kaiser, W.: Kunststoffchemie für Ingenieure (Plastics chemistry for engineers), 2nd edition, Carl Hanser Verlag Munich (2007)

Determination of extractive and migratory substances from pharmaceutical plastic containers, dissertation, Susann Kaiser, 2010

Selke S.E.M., Culter J.D., Hernandez R.J. Plastics Packaging Properties, Processing,

Applications and Regulations, 2nd edition, Carl Hanser Verlag Munich, 2004

Batzer H. Polymer Materials – Chemistry and Physics, Volume I, Thieme Verlag Stuttgart, 1985

Batzer H. Polymer Materials – Technology 1, Volume II, Thieme Verlag Stuttgart, 1984