Encapsulation: Innovative technologies for cosmetic products

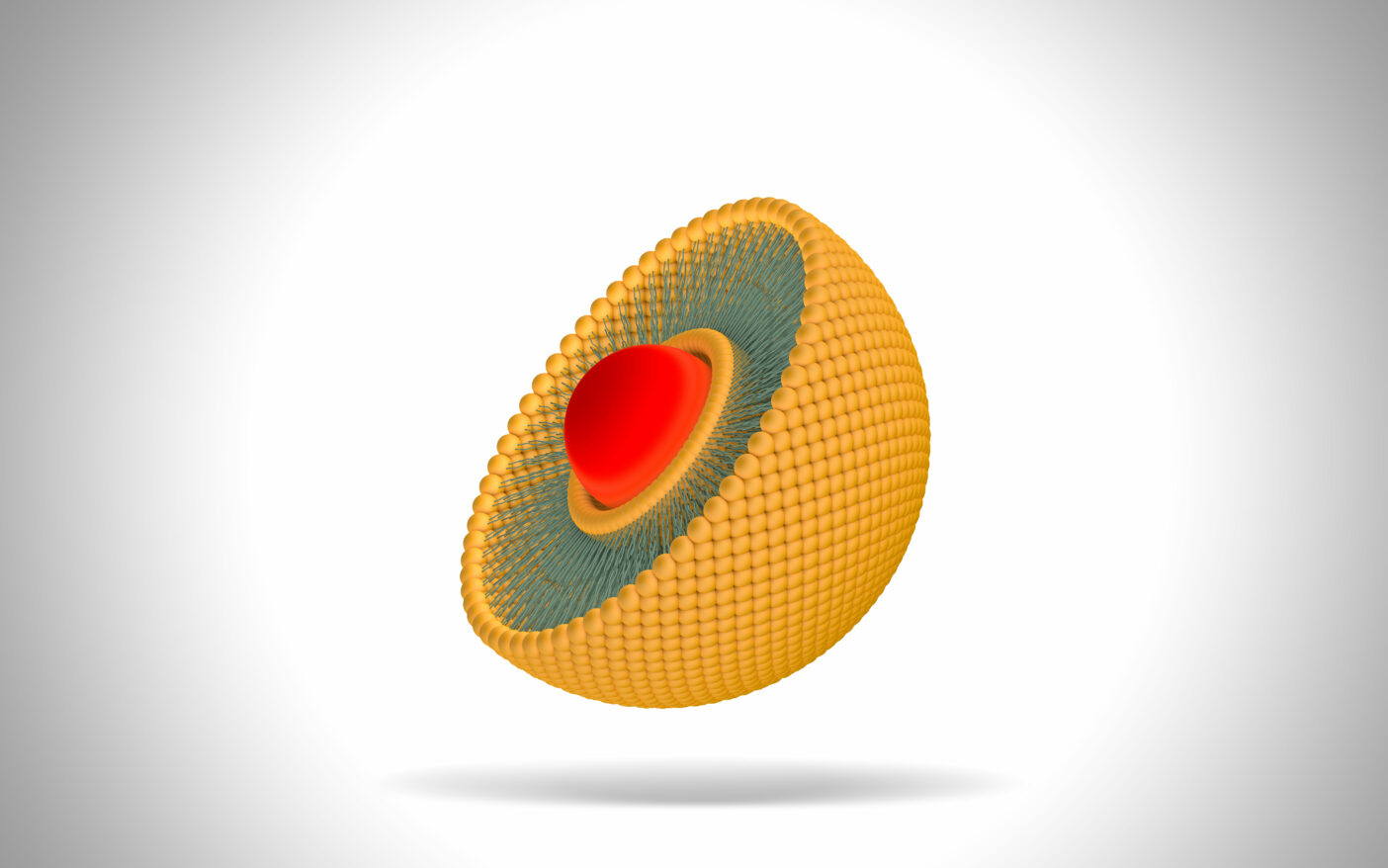

In modern cosmetics, encapsulation is a key tool for protecting sensitive ingredients, increasing their bioavailability or creating special visual effects. It opens up completely new formulation options and enables the targeted control of active ingredient release.

Encapsulation technologies have developed rapidly in recent years. In addition to the classic approaches, there are now novel methods that can stabilize active ingredients even better, protect them from oxidation and control their release individually.

Cyclodextrins – protection and solubility improvement

Cyclodextrins are among the most versatile forms of encapsulation. They exist in three sizes (α-, β- and γ-cyclodextrin) and are capable of converting lipophilic substances into water-soluble forms without altering their chemical structure.

Examples of applications:

• Solubilisation and stabilisation of sensitive active ingredients

• Protection against oxidation and decomposition

• Odour reduction or masking

• Improvement of skin absorption.

Current research results show that cyclodextrins can also significantly increase the effectiveness of plant-based active ingredients such as curcumin or cannabinoids.

Microencapsulation of fragrances

The encapsulation of fragrances is particularly interesting for products such as deodorants, shampoos and body lotions. Targeted capsule structures allow the fragrance to be released repeatedly over a period of hours.

Recent developments make it possible to adapt the release rate to the individual requirements of the product – for example, through temperature- or friction-activated capsules that only release their contents upon contact with the skin.

Encapsulation of dyes – for visual effects

The encapsulation of dyes enables surprising formulations: an outer shell in a different colour from the inner core creates stunning visual effects. When applied, the capsules break and release the dye. This is ideal for sunscreen products with application indicators or innovative hybrid make-up products.

Advances in pigment technology now enable colour capsules that are additionally loaded with UV filters or antioxidants.

Soft capsules – luxury for the skin

Soft capsules are hydrogel microcapsules that dissolve easily on the skin. This form of encapsulation is ideal for high-quality serums, facial care products or spa products.

Advantages

• Can be loaded with lipids, colours or active ingredients

• Visual enhancement (pearl or caviar look)

• Can be formulated without traditional emulsifiers

Hard capsules enable targeted release

Hard capsules made from natural or synthetic materials can serve as time-controlled active ingredient depots. This encapsulation ensures that the ingredients are only released after a certain exposure time.

Possible applications:

– Vitamins, plant extracts or oils

• Colour-coded indicators for functional substances

– Prolonged massage or care effects

Hydrophilic spray drying

This process allows water-soluble substances to be stably encapsulated at temperatures ranging from +30 °C to 230 °C. This encapsulation enables complex multi-layer coatings, agglomerations (‘raspberry shape’) or granulated beads and is therefore ideal for powder formulations or O/W emulsions.

Encapsulation of lipids and fats

The encapsulation of hydrophobic substances such as natural oils, butters or W/O emulsions protects sensitive raw materials from oxidation and improves their processability.

Newer hot-melt coating processes allow uniform coating even at low temperatures. This is particularly relevant for heat-sensitive active ingredients.

Why encapsulation is a game changer

Encapsulation offers decisive advantages:

– Protection of sensitive raw materials from light, oxygen and moisture

– Controlled and delayed release of active ingredients

– Masking of unpleasant odours or tastes

– Improved skin compatibility through lower active ingredient concentrations with the same effect.

– Optimised flow properties and processing reliability in powders and granules.

Modern technologies can thus significantly increase not only the shelf life and effectiveness of cosmetic products, but also their appeal.

Conclusion

Encapsulation is no longer just a trend – it is a key factor for effective, stable and innovative cosmetic products.

Whether for stabilising sensitive active ingredients, creating impressive visual effects or for targeted release: encapsulation makes all the difference.

💡 Cosmacon develops tailor-made formulations with encapsulated active ingredients, ensuring that your products achieve maximum effectiveness and stability.

Would you prefer to purchase finished products? At Tojo Cosmetics, you can obtain exclusive private label products with innovative encapsulation that are immediately market-ready and ready for use.